Improve time to market with a scalable technology for efficient microfiltration and ultrafiltration

From lab scale to production, we serve you all the way!

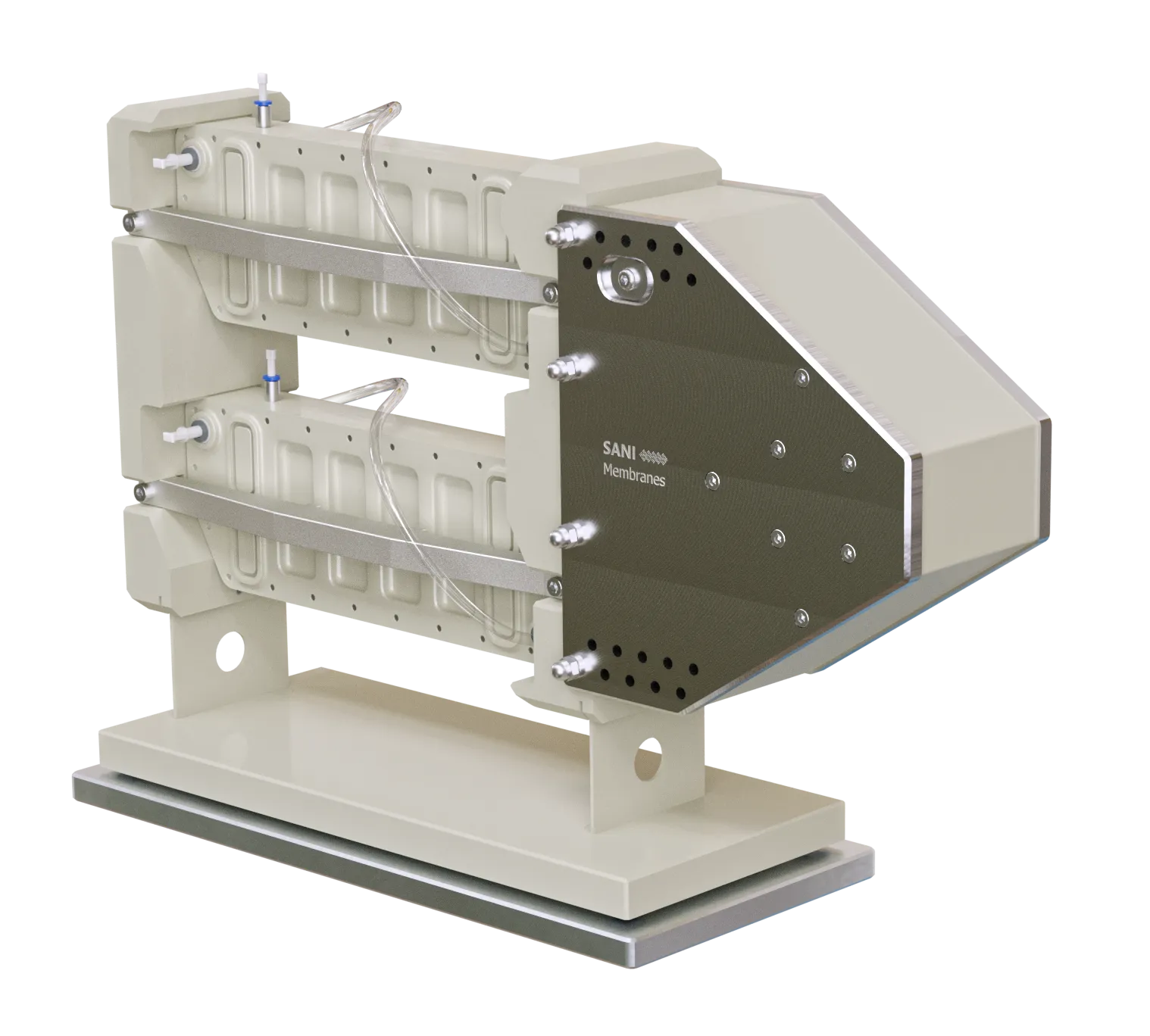

Vibro-Lab35P

35 cm² membrane surface area

Process development with extremely low volumes

Scalable continuous membrane filtration

The Vibro-Lab35P improves process development of continuous microfiltration/ultrafiltration since the system is scalable to large industrial units.

Small feed volumes

The Vibro-Lab35P allows you to do continuous filtration with down to 50 mL feed as the retentate dead volume is only 8 mL.

Easy to understand

The Vibro-Lab35P reduces the complexity of membrane filtration due to the patented Vibro® technology and the Free Flow plates.

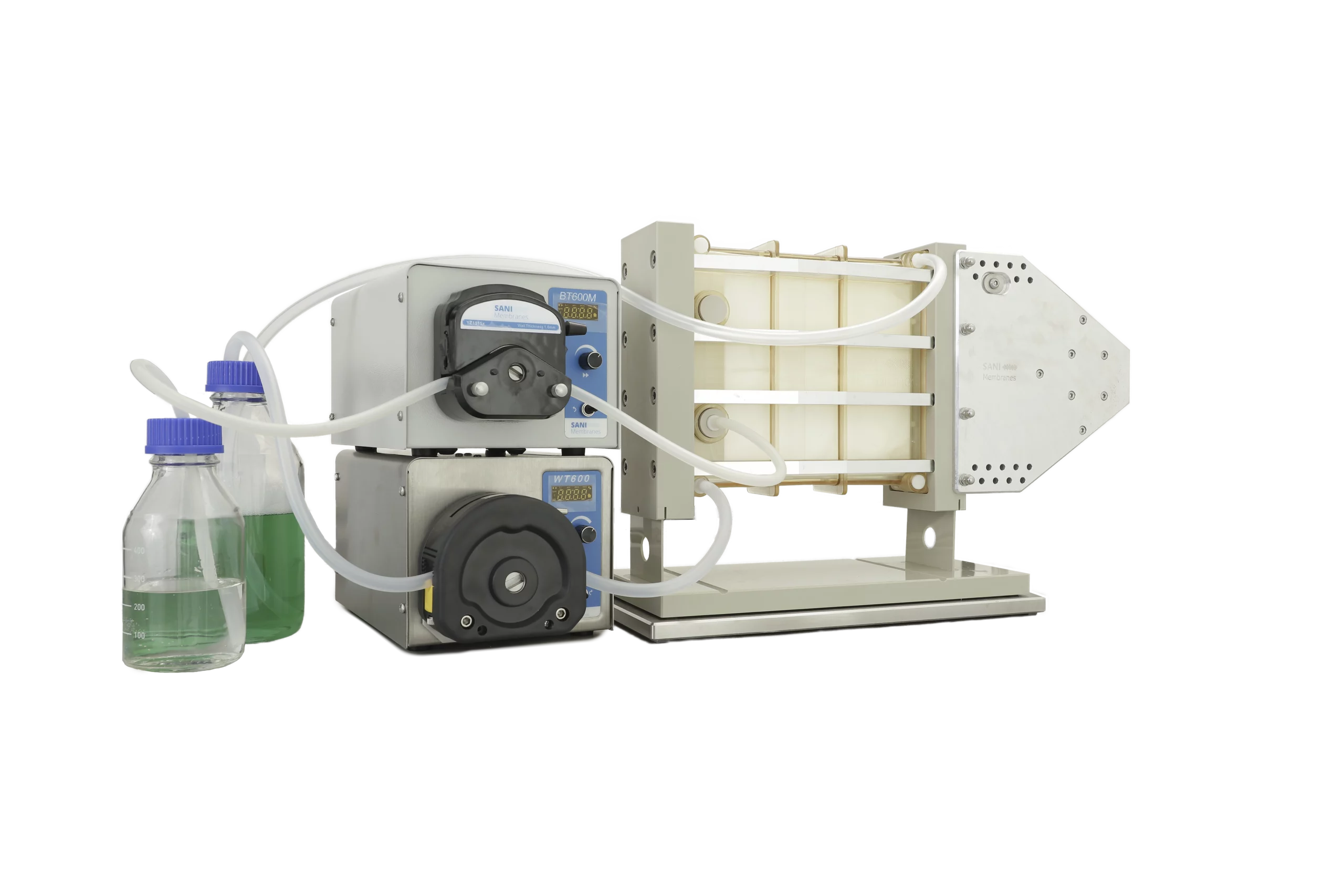

Vibro-Lab280

Can be equipped with 1 or 2 cartridges of 280 cm² membrane surface area

Superior flexibility and ideal for small bioreactors and laboratories

Superior recovery

With Vibro® Technology, you can recover up to 100% of API due to the fully drainable membrane modules.

Faster process development

The Vibro-Lab280 is the ideal solution for benchtop filtration and process development. The unit fits 1 or 2 cartridges, giving you a large span in working volume to work with.

Easy setup

The reduced complexity with Vibro® filtration makes it simple to setup and connect as the crossflow pump is redundant and cooling not needed.

Vibro-Lab3500

3500 cm² membrane surface area

Improved process development – transparent and scalable

Easy to understand and use

The Vibro-Lab3500 reduces the complexity of membrane filtration due to the patented Vibro® Technology and Free Flow Plates.

Improved process development

The Vibro-Lab3500 is the ideal equipment for process development and membrane screening. The see-through housing makes it possible to observe all membrane area during process and cleaning.

Easy setup

The reduced complexity with Vibro® Filtration makes it simple to setup and connect, as the crossflow pump is redundant and cooling not needed.

Vibro-I

2.5 m², 10 m², 20 m², 40 m² or 80 m² membrane surface area

Industrial membrane filtration with optimal process control

Optimal separation with extremely low pressure

The Vibro® Technology makes it possible to run the separation with 100% uniform and extremely low TMP. Thus, improving separation and making actual microfiltration possible.

Perfect for food and pharmaceutical production

All engineering solutions are sanitary and all parts in media contact are in FDA / EC 1935/2004 compliant materials.

Energy consumption reduced by up to 95 %

The Vibro® Technology makes the crossflow pump redundant and as a result, the energy requirements for pumping and cooling are reduced.

Vibro-I Feed System

Feed system for Pilots and small scale

Vibro-I systems

Easy to use – Plug and play feed system

The Vibro-I Feed System with intuitive controls and datalogging is delivered on a frame and can easily be connected to a Vibro-I.

Suitable for food and pharma production

All engineering solutions are sanitary and all parts in media contact are in FDA / EC 1935/2004 compliant materials.

Small footprint and movable

The Vibro-I Feed System can be used in any lab due to the small footprint. Furthermore, the system is on wheels.

Testimonials

Mipsalus

“The Vibro® technology minimizes cake formation in the filtration process, so we are able to get very large quantities through with a high quality. At the same time, there is extremely low energy consumption”

Nicolas O. Krogh, CEO

Novozymes

”The Vibro-I filter is a robust solution, simple to use with no technical issues and with good flux. Power consumption under all operations (microfiltraiton/ultrafiltraion) are much lower than in any known filter technology.”

Science Manager

Imerys

”We achieved nice results with this technology, even beyond our imagination”

Erika Bartolomei

Process Engineer, PhD