Dairy & Liquid Food

SANI Membranes is a trusted partner for filtration in dairy and liquid food applications

The Vibro® technology can replace microfiltration and ultrafiltration ceramic and plate-and-frame cross flow systems with easy-to-service, low-cost systems. The Vibro® technology makes it possible to work with very high viscosities in a simple and affordable solution with minimal energy consumption being used for pumping, thereby also minimizing cooling requirements.

As the transmembrane pressure (TMP) is uniform in the entire system, the separation cut-off is very sharp. Meaning that a better fractionation of molecules is achieved. The Vibro® technology can work with exceptionally low TMP (e.g. 0.1 bar), which enables true continuous microfiltration.

Low energy consumption – Up to 95% reduction

High concentration, viscosities and solid loads – replaces costly ceramic or P&F solutions

Gentle product handling – Minimal pump shear

Reduced CIP time – Fully drainable membrane modules

Ideal separation – better products, sharper cut-off

The Vibro® technology is typically used within the following separation steps:

Initial separation of cells/solids/large molecules from proteins/small molecules/water:

The Vibro® technology makes it possible to run continuous microfiltration, making the solution ideal for separation of raw streams. This enables you to achieve a high yield and better-quality products in both permeate and retentate.

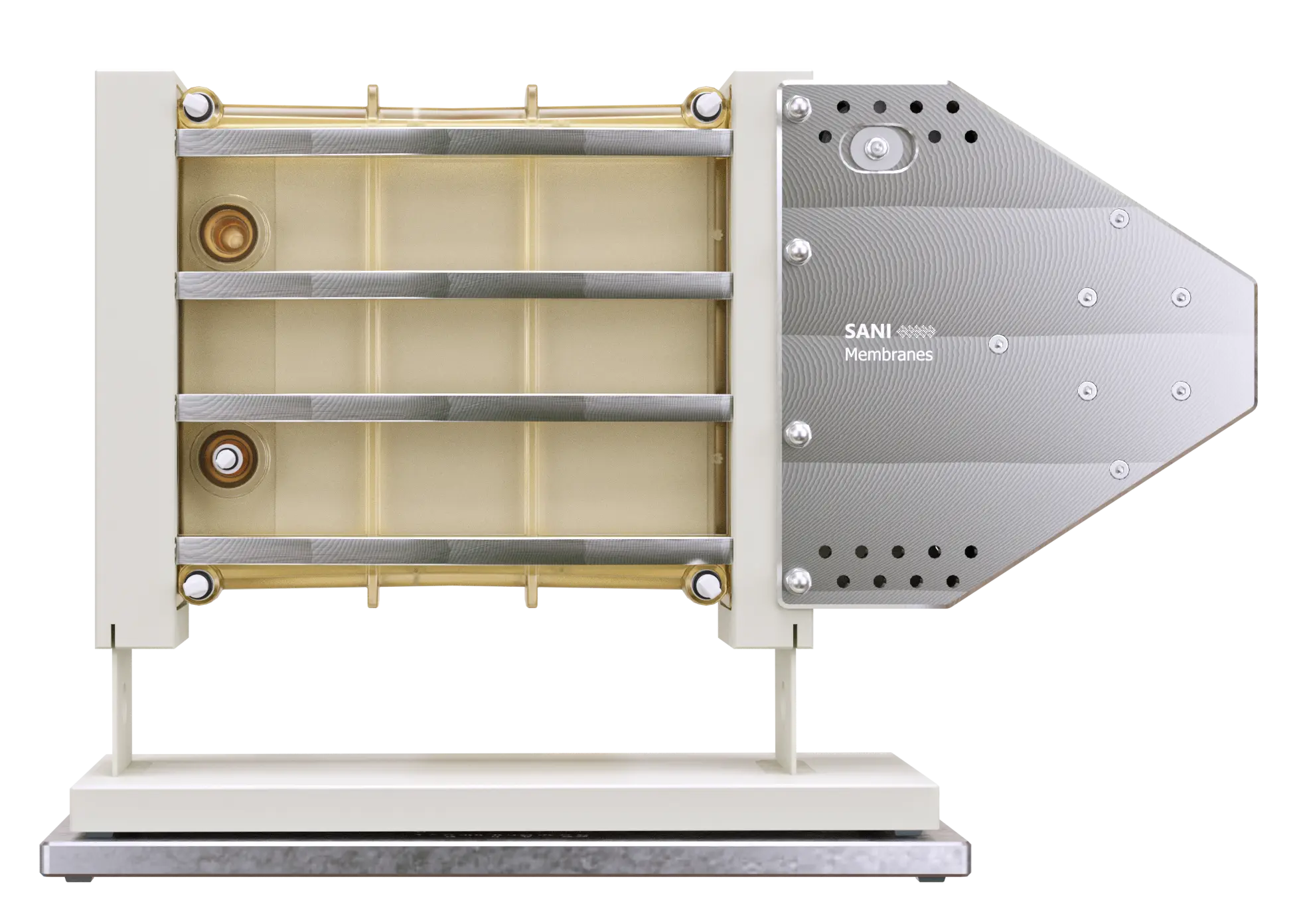

- The Vibro® technology can handle high solid loads and high viscosities due to the open design of the Free Flow Plates™.

- For fractionation of raw streams, the Vibro® technology can achieve an extremely high recovery due to the low TMP, which makes it possible to control the fouling layer and achieve high transmissions of target compounds.

Concentration of protein:

The Vibro® technology makes it possible to achieve a high concentration of protein due to the open and clean design of the Free Flow Plates.

The Vibro® technology creates the following benefits

Reduced energy consumption

With the Vibro® technology, it is possible to reduce the energy consumption by up to 95% since the cross flow pump is redundant.

Improved separation

With the Vibro® technology the separation is improved due to the uniform TMP, which ensures that the membranes’ molecular weight cut-off (MWCO) is uniform throughout the system – Even for industrial plants.

Reduced product shear

With the Vibro® technology, the cross flow pump is replaced by vibrations. This enables very gentle filtration, thereby reducing product shear to a minimum.

Actual continuous microfiltration

With the Vibro® technology, it is possible to do actual microfiltration due to the low and uniform TMP.

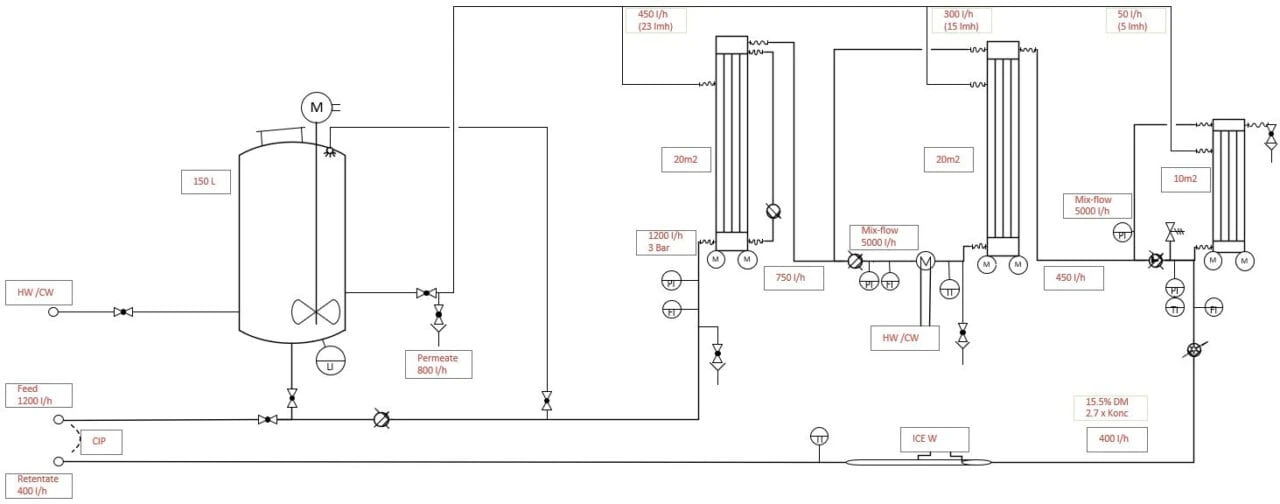

Industrial Example:

The Vibro® technology is in the following example applied for a Greek Yoghurt process where the cultured skim milk is concentrated to Greek Yoghurt.

Description:

The cultured milk is processed in a Vibro-I unit with 3 steps. The first step is with plug flow and the second and third step is with mix flow (a very slow cross flow – mixing the retentate in the unit). The shown unit is for 1200 l/h skim milk with 450 l/h concentrate produced. The system footprint is 2 x 2 meter and the power consumption for pumps is less than 5 kW. This also means that only very little cooling is needed. The system is simple to use, easy to CIP and requires minimal control.

From lab scale to production, we serve you all the way

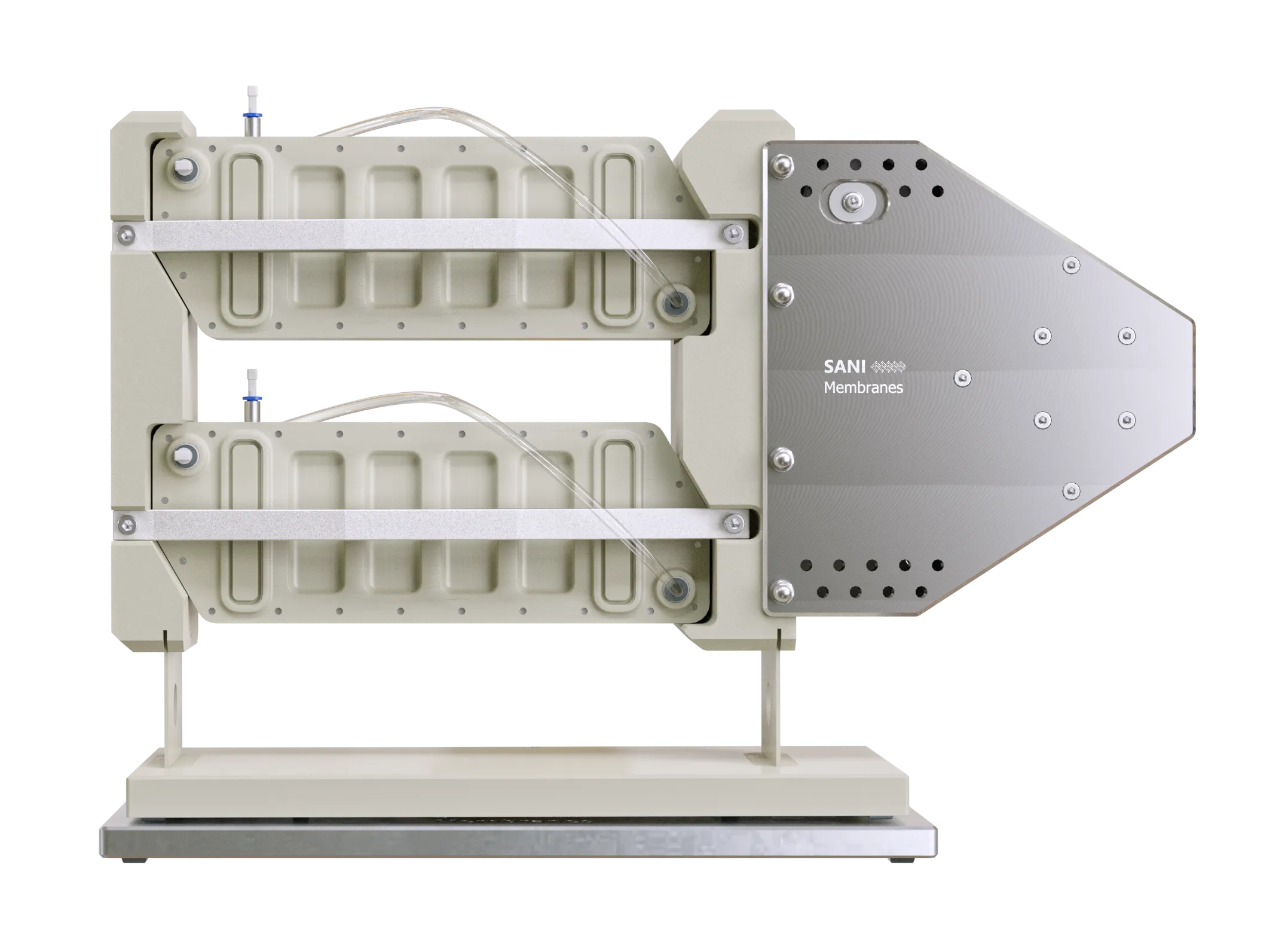

Vibro-Lab35P

Process development with extremely low volumes

Vibro-Lab3500

Improved process development – transparent and scalable

Request demo

Fill in your contact information if you are interested in learning more about Vibro technology.

When filling in the data form, you accept receiving digital communications from SANI Membranes. In order to withdraw your acceptance, please contact info@sanimembranes.com