Technology

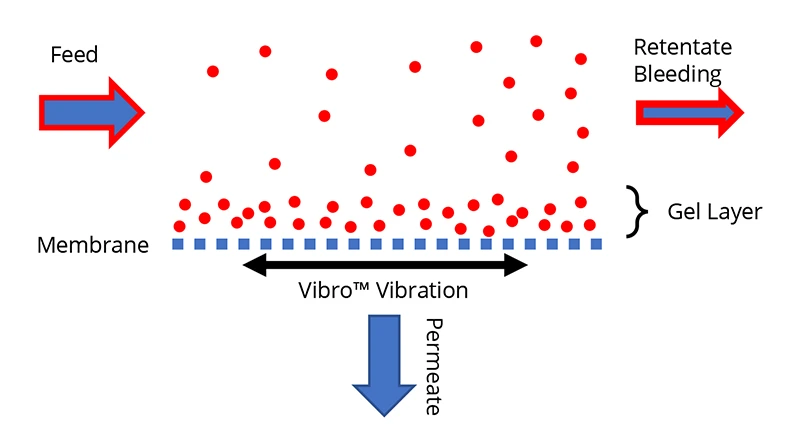

SANI Membranes has developed a new and patented membrane filtration technology based on the Free Flow Plate™ modules and the Vibro® technology.

Vibro® technology delivers efficient continuous microfiltration and ultrafiltration with less fouling, less energy consumption and a simple and sanitary design.

The technology is based on the cross flow filtration principle, but the turbulence at the membrane surface is here created by vibrating the membrane relative to the feed instead of applying a fast cross flow.

Turbulence is only produced at the membrane surface and the huge pressure loss from a traditional cross flow is eliminated. As a consequence the transmembrane pressure (TMP) becomes close to uniform throughout the system, making unique process control and sharper separations possible.

Cross Flow Filtration/Tangential Flow Filtration vs. Vibro® Filtration

Fast flow creates turbulence and pressure loss

Circulation pump affects product and uses energy

Energy extensive cooling is needed

Vibration creates turbulence on surfaces

No pressure loss – uniform TMP

Turbulence only where needed! Minimal cooling needed

Benefits of Vibro® Technology

Vibro® technology is a microfiltration and ultrafiltration solution with several benefits compared to conventional filtration systems:

Ideal separation

Improved separation due to a sharper cut-off. Eliminating the cross flow pump leads to a system with minimal pressure loss. The result is a close to uniform TMP in the entire system, securing a uniform cut-off over the entire membrane surface.

Unique filtration

Vibro® technology ensures the ability to run efficient microfiltration at extremely low TMP in the entire system (e.g. 0.10 bar). The low TMP reduces fouling and compaction and delivers continuous microfiltration with a super simple solution.

Less energy

Vibro® technology reduces the energy consumption by 50-95%. A cross flow system creates turbulence in the entire system whereas Vibro® technology only creates turbulence on the membrane surface where it is needed to reduce fouling.

Higher yield

The ability to run efficient microfiltration ensure a continuous high transmission of your target molecules leading to a yield increase of up to 25% compared to traditional technologies.

Eliminating manual work

With true continuous microfiltration you can replace costly and labor intensive single use filters. The Vibro® systems can be automatically maintained by Cleaning In Place, an environmentally friendly solution requiring no manual labor.

High concentration, viscosity and solid loads

Vibro® technology is ideal for membrane filtration of highly concentrated media due to the Free Flow Plate™ modules design with open free flow channels and no spacers.

Gentle product handling

Vibro® technology handles the product very gently as the elimination of the cross flow pump almost eliminates pump shear.

High recovery

The Free Flow Plate™ modules are fully drainable of both permeate and retentate – 100% of your product can be recovered.

Sanitary

Vibro® technology sets a new sanitary standard with the open and clean design of the Free Flow Plate modules without spacers and flow dead areas. Fouling starts later on flat surfaces and is easier to remove when formed – reducing CIP time and chemical loads for cleaning.

Membranes

The Vibro® filter elements are equipped with organic membranes in the range from 1 kDa to 1 µm from well known industry suppliers.

Standard ultrafiltration membranes are in the range from 1-800 kDa and are made in PES, PESH, PVDF, PAN or RC.

Standard microfiltration membranes are in the range from 800 kDa -1 µm and are made in PVDF or PTFE.

See our selection of membrane under the indiviual Vibro®unit or membrane module.

Contact us if you have special membrane requests.

Membrane filtration systems – Plant design – General considerations

Capacity of the membrane filtration system is relative to square meters of membrane within the system. Hence, the more square meters of membrane area in the filtration system, the higher the throughput.

Increasing the concentration of the media to be filtered will reduce the flux.

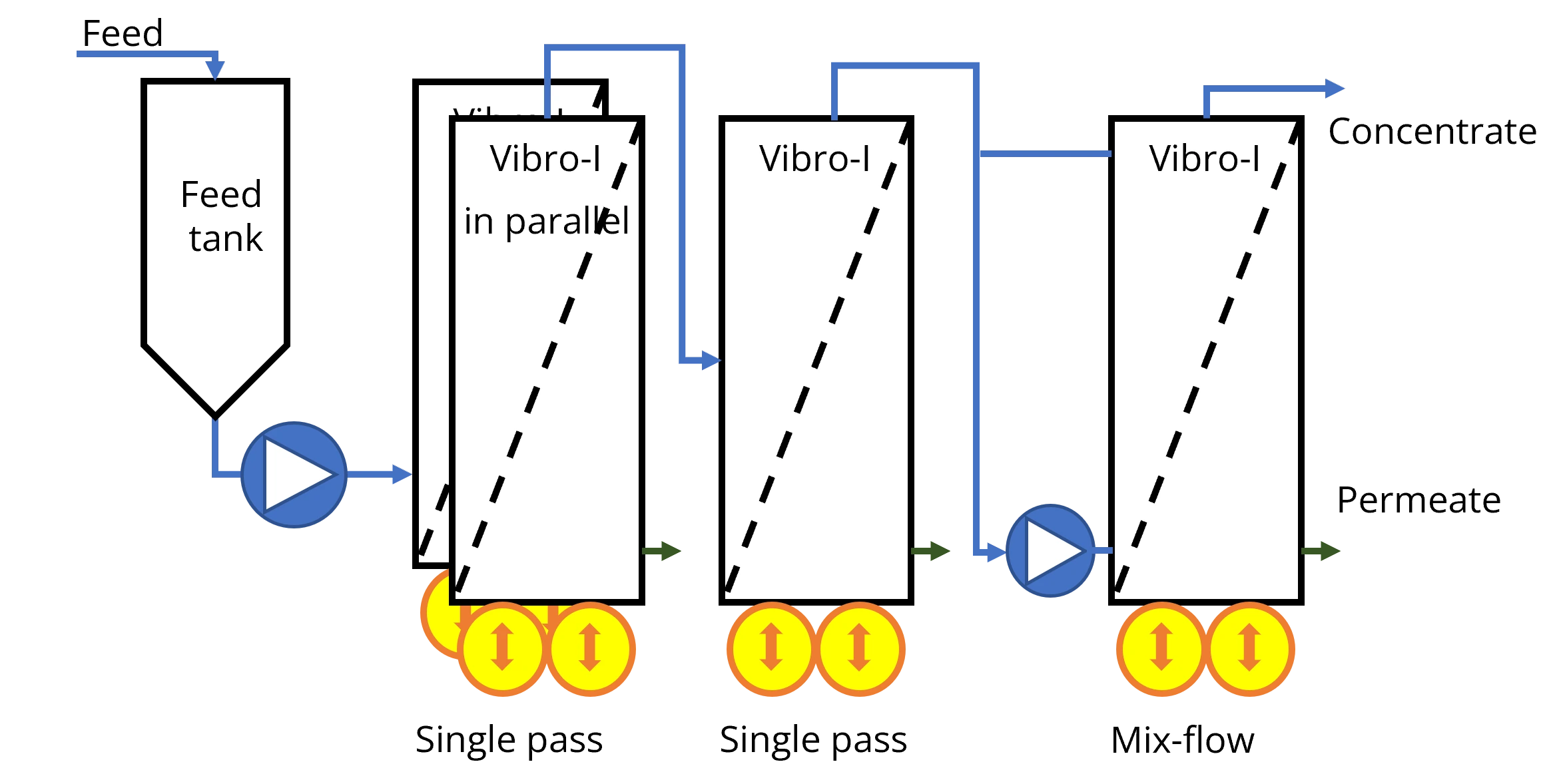

Vibro-technology – Specific considerations

Outgoing flow for each Vibro-I Unit: 800 l/h (Ranges 600-1400 l/h are OK).

Single pass = Optimal flux throughout pass.

For high transmission, use low TMP. Typically, permeate pump should run at 5-15 l/h.

Microfiltration most often has a flux optimum (e.g. yeast has a flux optimum at 0.2-0.6 Bar).

Vibro® units are easy drainable. System must be adapted for drainage.

Product recovery can be increased with drain of units.

Drainability reduces the need for water and chemicals during CIP.

Microfiltration flux over time will often be higher when using a 800 kDa membrane than a 0.45 Micron membrane.

We recommend designing the system based on pilot trial data with your specific product.

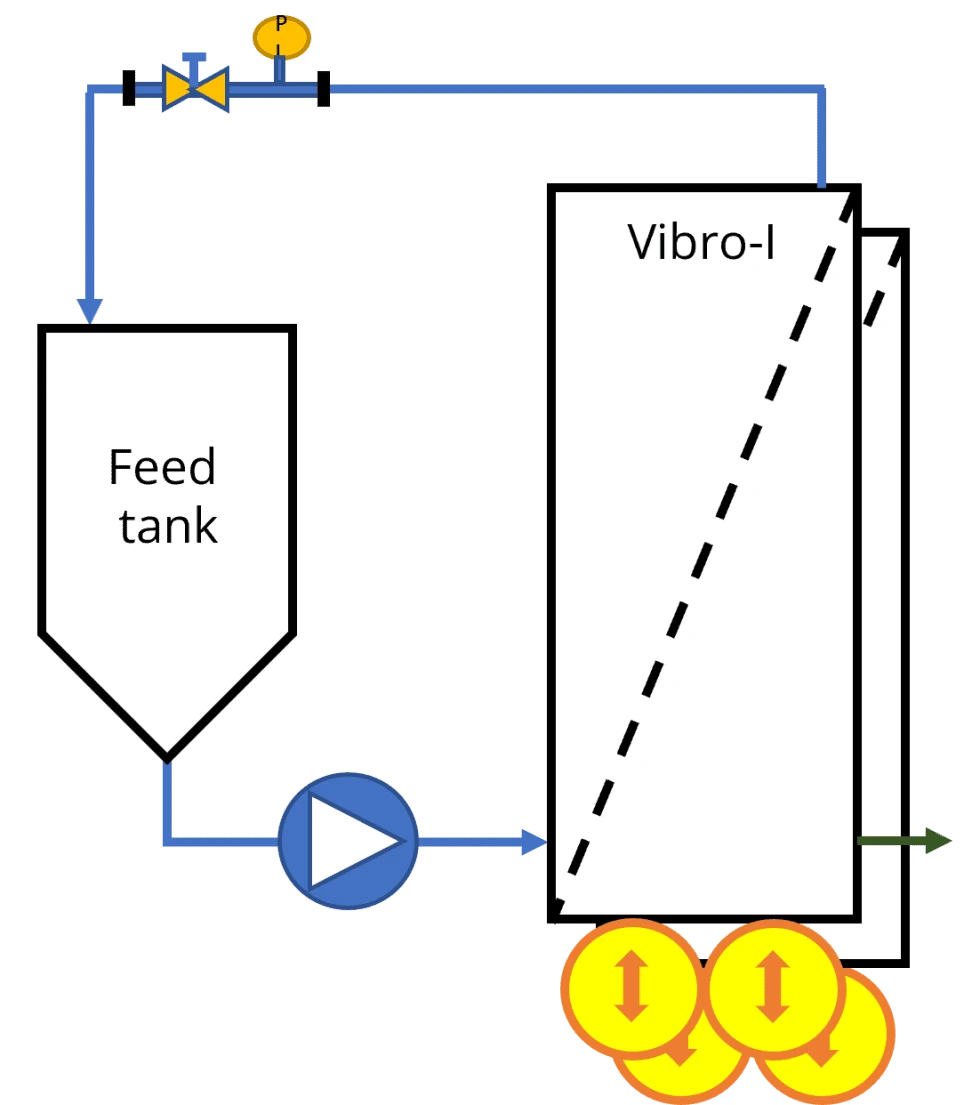

Membrane filtration in batch mode

Single or parrallel loops.

One batch between CIP’s.

Simple solution where the media batch can be concentrated to a highly viscous product.

Membrane filtration in batch mode typically has a higher flux per square meter membrane area than continuous operation.

Batch mode is ideal for filtration of products that are produced in batches.

Membrane filtration in continuous operation

Consecutive loops that can continue stable operations over many hours.

Flux decreases as concentration increases.

System can be adapted to concentrate to highly viscous, slurry-like consistencies.

Ideal solution for filtration of large volumes of media – or where risk of contamination of batch is high.

From lab scale to production, we serve you all the way

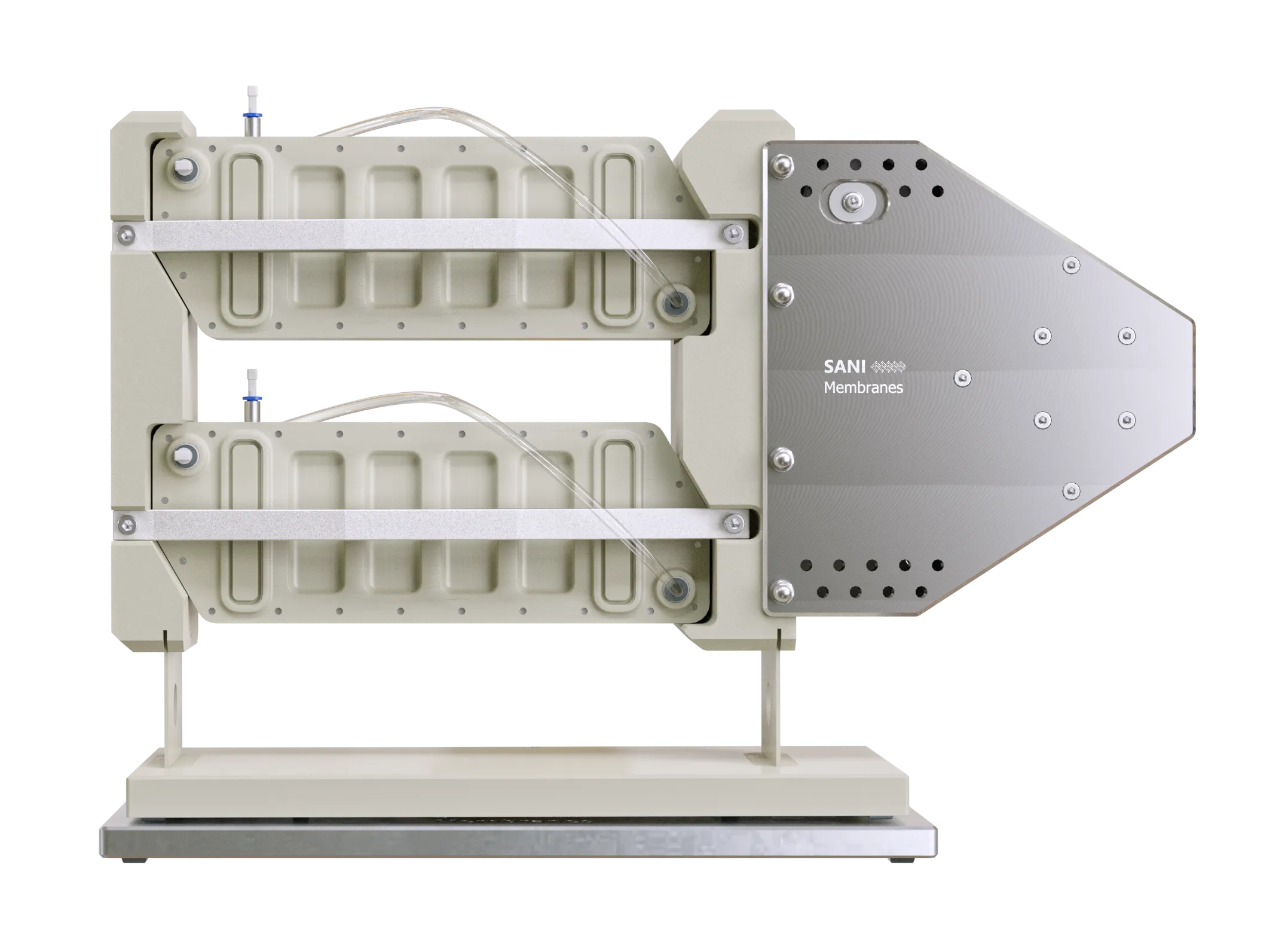

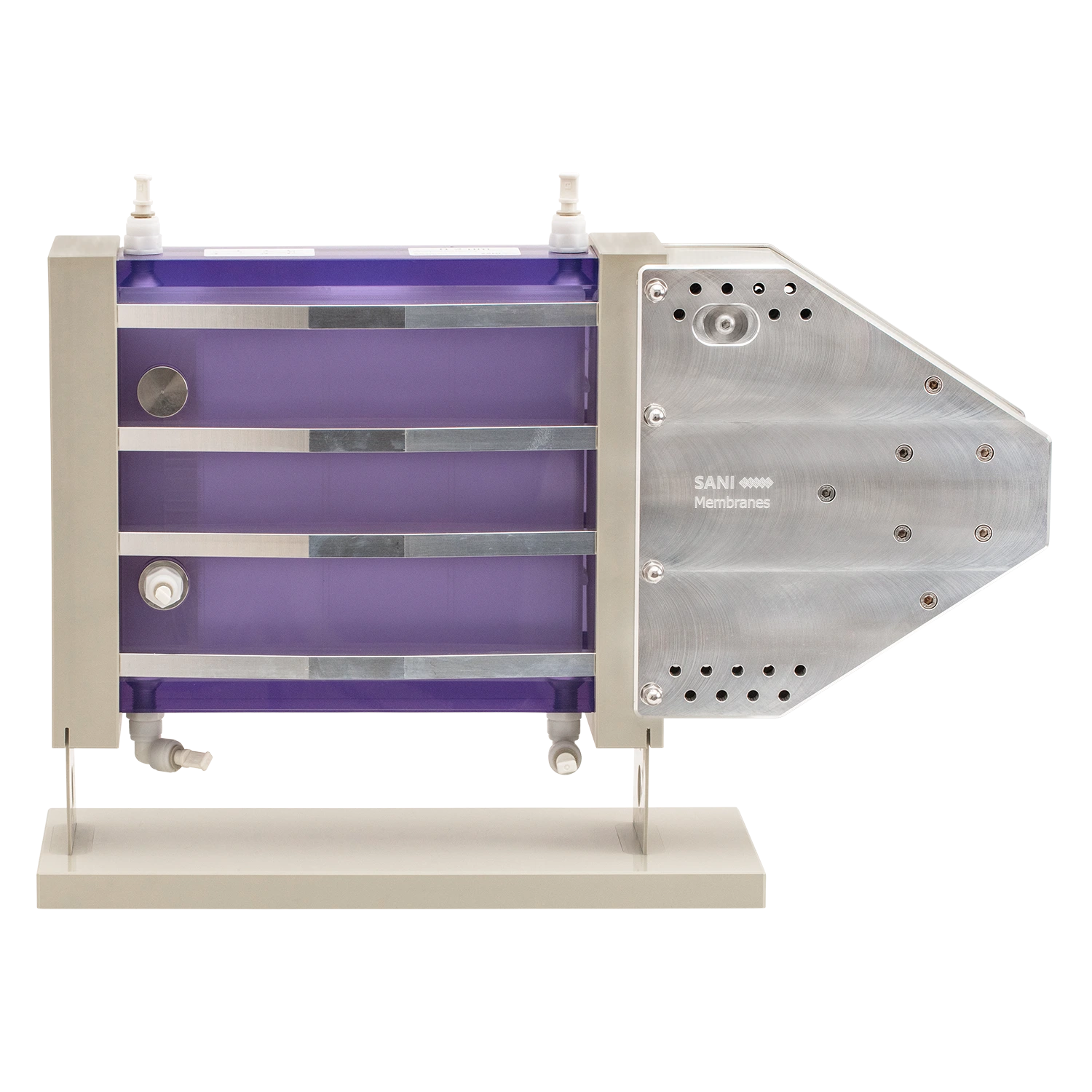

Vibro-Lab35P

Process development with extremely low volumes

Vibro-Lab3500

Improved process development – transparent and scalable

Request demo

Fill in your contact information if you are interested in learning more about Vibro technology.

When filling in the data form, you accept receiving digital communications from SANI Membranes. In order to withdraw your acceptance, please contact info@sanimembranes.com