Vibro-I

Industrial membrane filtration with optimal process control

Optimal separation with extremely low pressure

The Vibro® technology makes it possible to run the separation with 100% uniform and extremely low TMP. Thus, improving separation and making actual microfiltration a possibility.

Perfect for food and pharmaceutical production

All engineering solutions are sanitary and all parts in media contact are in FDA / EC 1935/2004 compliant materials.

Energy consumption reduced by up to 95 %

The Vibro® technology makes the crossflow pump redundant and as a result, the energy requirements for pumping and cooling are reduced.

Optimal separation even with extremely low pressure

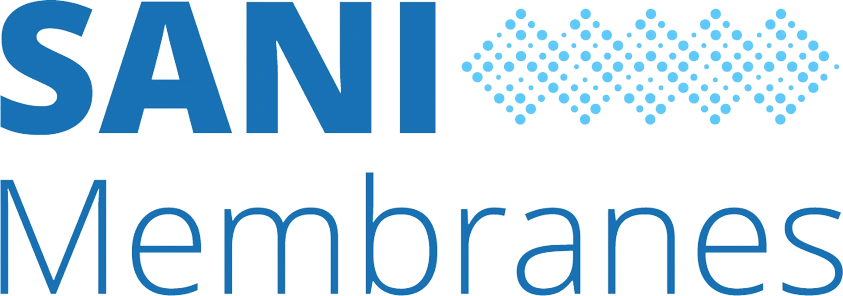

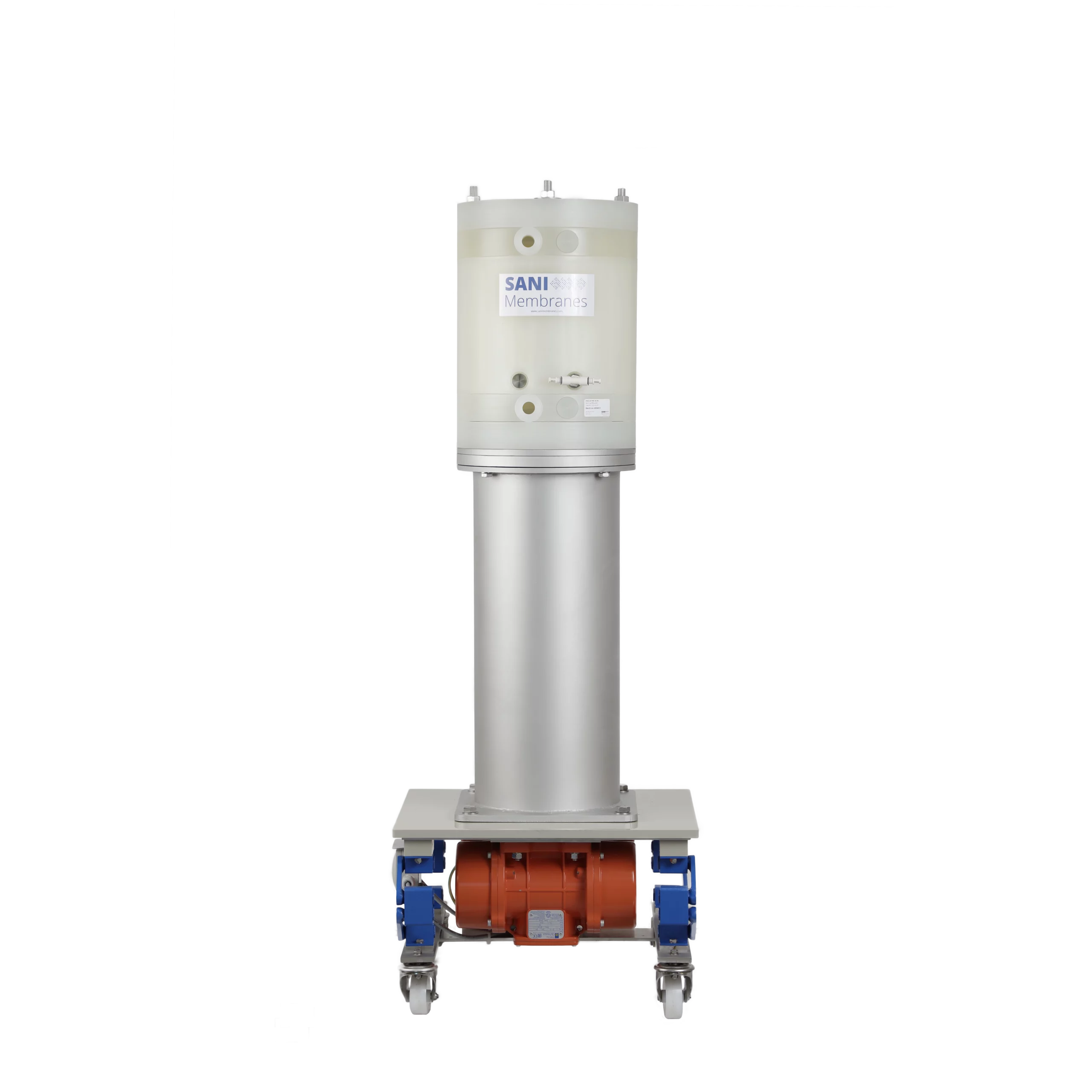

The Vibro-I is an industrial microfiltration and ultrafiltration solution for applications where low energy consumption, high flux, sanitary function, low capital investment and gentle filtration are key words. The cleansing turbulence on the membrane surface is achieved through vibration. This allows for truly uniform Trans Membranes Pressure (TMP) and secure optimal separation even at the extremely low pressures needed for continuous microfiltration.

Perfect for food and pharmaceutical production – Also at high concentrations

The Vibro-I has opened up for new applications and improvements of current applications for everyone using traditional microfiltration and ultrafiltration systems today.

The Vibro-I is ideal for food and pharmaceutical production as all engineering solutions are sanitary and parts in media contact are in FDA / EC 1935/2004 compliant materials.

Due to the open design of the HP1 Membrane Module, the Vibro-I can handle very difficult media with high viscosity, high mass loadings and even high particulates. When extremely difficult media are processed, it is possible to homogenize the retentate by attaching a ‘slow’ mix pump.

The Vibro-I has a sanitary design with a free flow path (no spacers) and is fully drainable of both retentate and permeate. Thus, no product loss and faster CIP cycles.

Energy consumption reduced by up to 95 %

Vibro-I is scalable from pilot scale to production, using the modular and stackable filter modules.

The tower configuration and the elimination of the crossflow pump, cooling and intricate piping layout gives the Vibro-I systems a small footprint and reduces energy consumption by up to 95 %.

Scaling simplified

When you want to simulate full scale production processes and move your process from the laboratory scale to industrial production, your separation process needs to meet critical quality attributes.

With Vibro® filtration, the process is the same across all units, meaning that your results will be the same regardless of which unit you are using.

Additionally, the uniform TMP grants you superior process control, simplifying the process of reaching your targeted quality attributes.

The small benchtop units are therefore ideal for both process development and for simulating large scale production with reliable projections. The Lab-series units can easily be substituted or supplemented by larger units to scale up and reach full scale production.

As the Vibro-I units are modular, they can work in unison and you can keep scaling your production without having upper limitations on capacity.

Vibro-I 2.5 m²

Vibro-I 10 m²

Vibro-I 5 m²

Vibro-I 20 m²

Vibro-I 80 m²

Accessories

Vibro-I Feed System:

The Vibro-I Feed System can be used with the Vibro-I for any kind of microfiltration and ultrafiltration application up to 80 m². The Vibro-I Feed System consist of a feed pump, mix flow pump, CIP tank, Pressure & temperature indicators and control cabinet including HMI.

HP1 Membrane module:

The HP1 Membrane modules are delivered in a wide range of materials and with a pore size between of 1 kDa to 1 µm.

Request demo

Fill in your contact information if you are interested in learning more about Vibro technology.

When filling in the data form, you accept receiving digital communications from SANI Membranes. In order to withdraw your acceptance, please contact info@sanimembranes.com