Simplify filtration of cell culture (perfusion, clarification) with the Vibro S series

Next level of process intensification

Supports applications from 50 mL to 20,000 L

Vibro Membrane Filtration (VMF) enables next level of process intensification with results not possible with any other filtration technology (ATF/TFF). With the addition of the new, sterile Vibro S series, the benefits of VMF is now also supporting processes that require sterile filtration devices, such as perfusion/continuous processes, cell harvest, cell recovery, processing of monoclonal antibodies (mAbs), vaccine production or stem cells.

The Vibro S series is similar to non-sterilizable Vibro units, allowing easy scale-up/scale-down of processes and enabling the high yield and recovery rate that characterizes VMF.

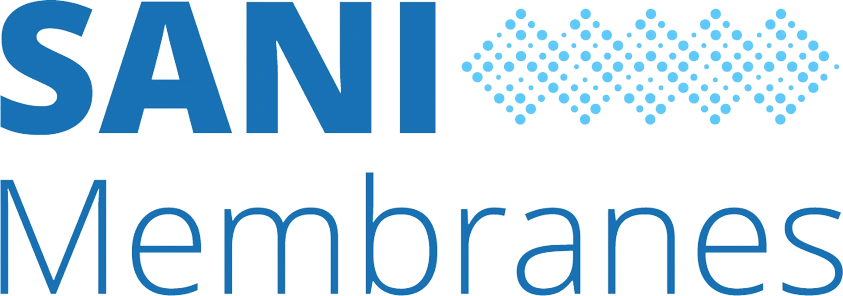

Vibro-Lab35S

35 cm² membrane surface area

Process development with extremely low volumes

Scalable continuous membrane filtration

The Vibro-Lab35S improves process development of continuous microfiltration/ultrafiltration since the system is scalable to large industrial units

Small feed volumes - High throughputs

The Vibro-Lab35S enables continuous filtration with as little as 50 mL feed in a completely drainable system

Process intensification

Reach higher cell densities and product concentrations. Intensify seed train and cell bank

Less membrane fouling

VMF enables higher product recovery with minimal membrane fouling

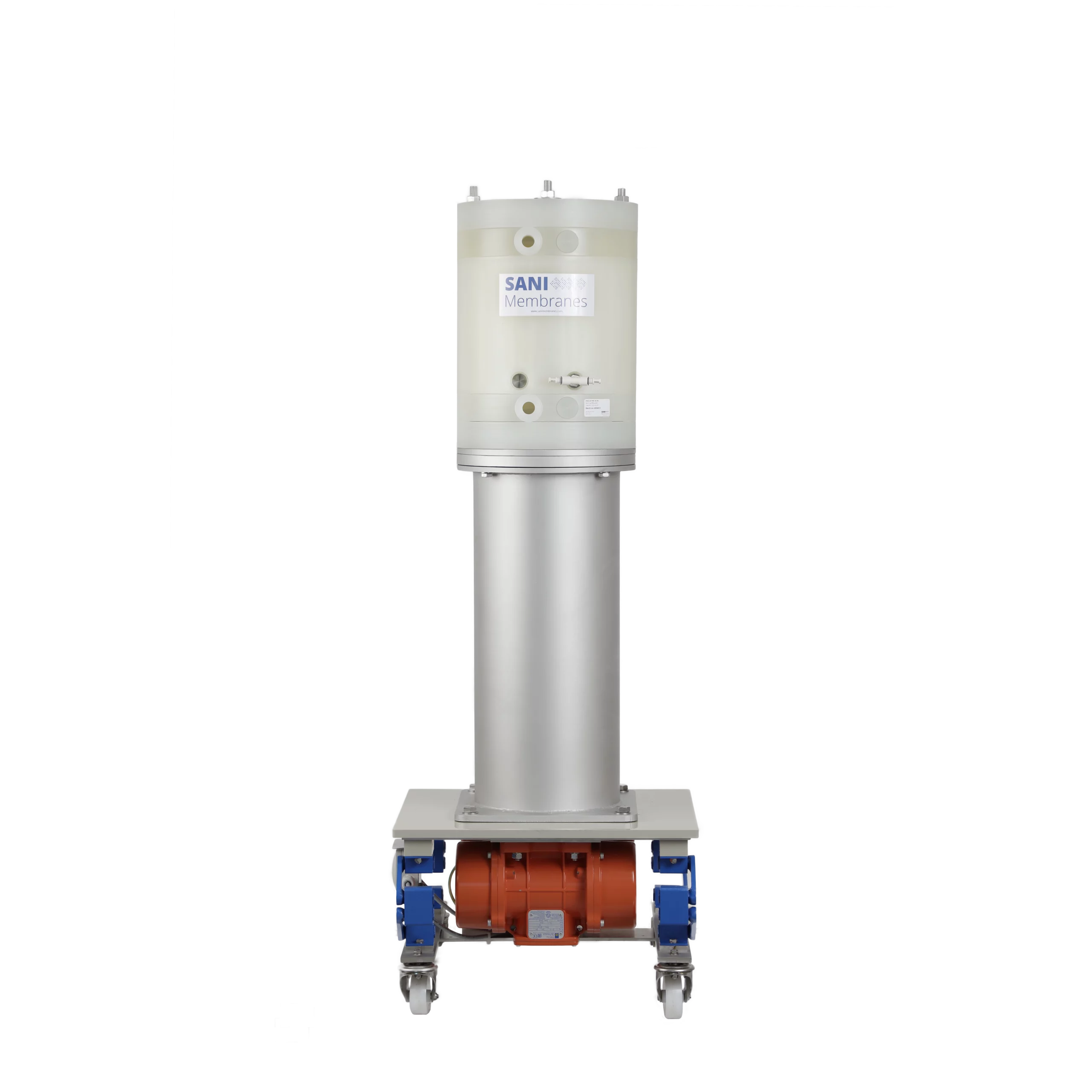

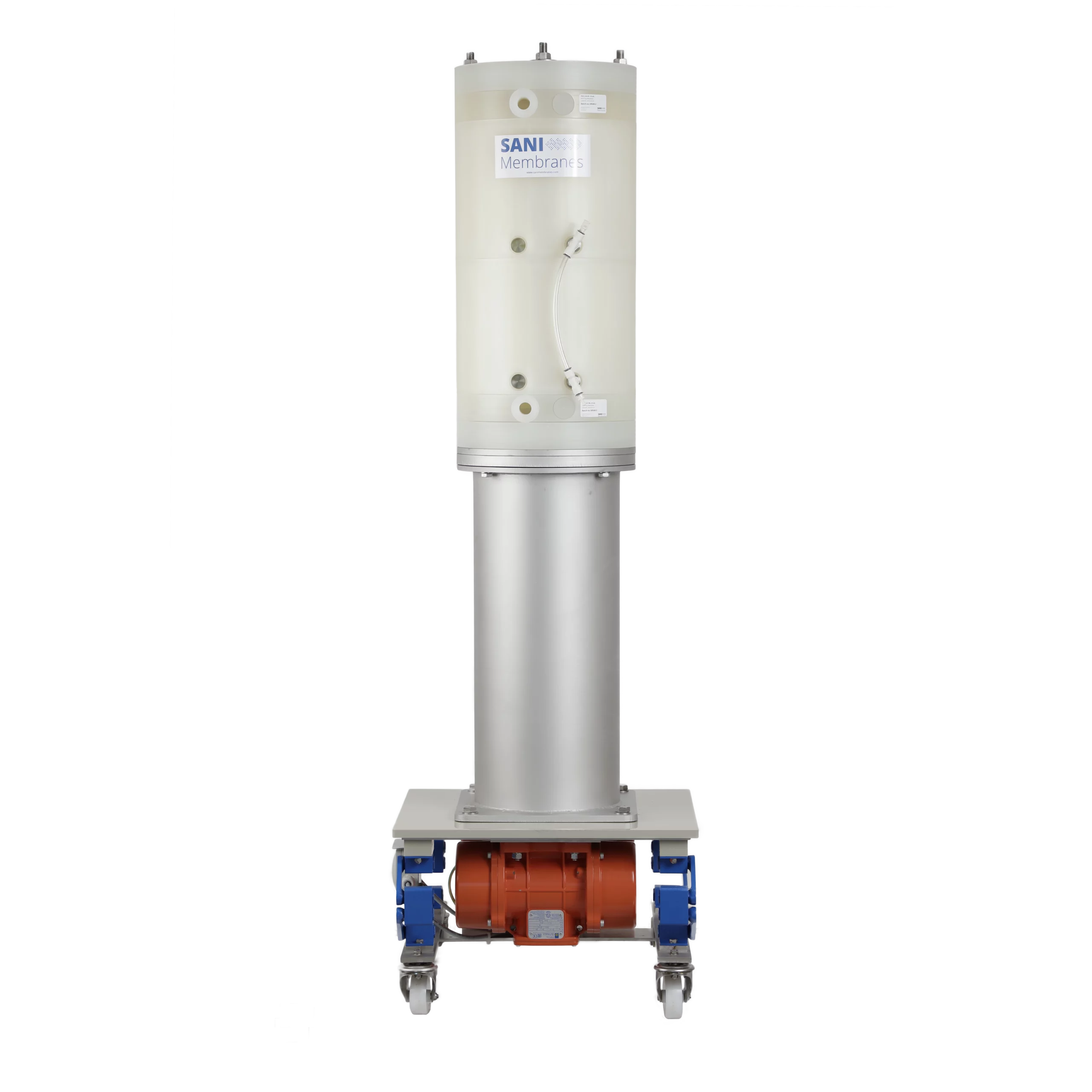

Vibro-Lab3500S

3500 cm² membrane surface area

Simplify and intensify

Process development and process intensification

The Vibro-Lab3500S is the ideal equipment for process development and process intensification in both lab and pilot scale. The transparent housing makes it possible to observe all membrane area during process or draining step

Smallest device with Free Flow Plate Technology

Ideal for scale-up or scale-down from Vibro-I devices

Simple setup and low energy consumption

No need for crossflow pump, cooling systems, compressed air or vacuum pump/compressor

Vibro-I S

2.5 m², 5 m² and 10 m² membrane surface area

Efficient, robust and sustainable

Optimal separation with extremely low TMP

The Vibro® Technology makes it possible to run the separation with 100% uniform and extremely low TMP. Thus, improving separation and making actual microfiltration possible

Easy setup - Low CAPEX

No need for crossflow pump, cooling systems, compressed air or vacuum pump/compressor

Sustainable

Low energy consumption, recyclable materials, no glues

Expected release

Q4 2024

Vibro-I S 40 m²

40 m² membrane surface area

Largest sterile membrane filtration device available

Up to 20,000 L applications with extremely low TMP

The Vibro® Technology makes it possible to run the separation with 100% uniform and extremely low TMP. Thus, improving separation and making actual microfiltration possible

Easy setup - Low CAPEX

Small footprint and simple design compared to other technologices. No need for crossflow pump, cooling systems, compressed air or vacuum pump/compressor

Sustainable

Low energy consumption, recyclable materials, no adhesives

Expected release

Q1 2025

Testimonials

Mipsalus

“The Vibro® technology minimizes cake formation in the filtration process, so we are able to get very large quantities through with a high quality. At the same time, there is extremely low energy consumption”

Nicolas O. Krogh, CEO

Novozymes

”The Vibro-I filter is a robust solution, simple to use with no technical issues and with good flux. Power consumption under all operations (microfiltration/ultrafiltration) are much lower than in any known filter technology.”

Science Manager

Imerys

”We achieved nice results with this technology, even beyond our imagination”

Erika Bartolomei

Process Engineer, PhD